Fine Wire Staple

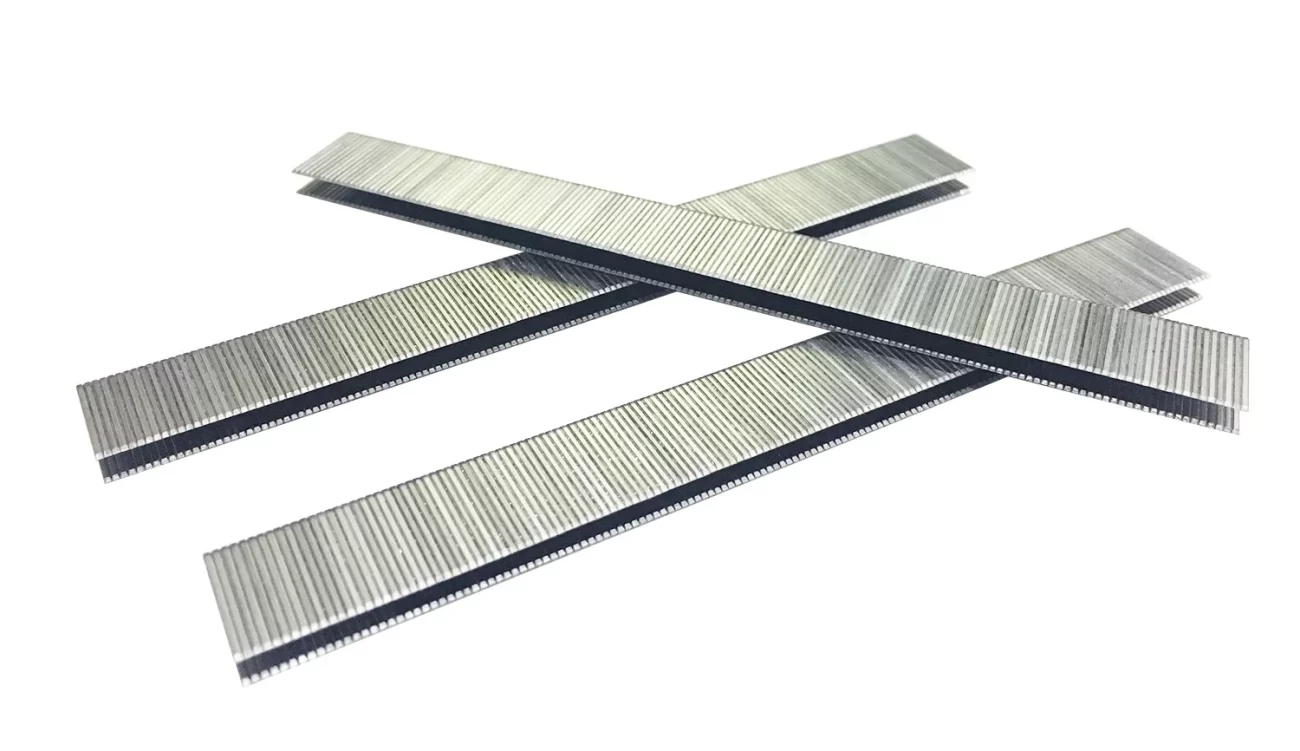

Fine Wire Staples

Fine wire staples are ideal for attaching fabrics, thin metal labels, wire mesh and thin strips of wood, for example.

Fine wire staples are thinner thanflat wire staplesand thus destroy as little tissue as possible.

Staple Material

Galvanized

staples

- Zink coating for corrosion protection.

- Long life.

- Less durable than a stanless steel staple.

General use staple with a good durability and strength.

Copper coated

staples

- Beautiful and clean aesthetics

- Works better in non humidity controlled environment

- Oxidise faster in salty environments

Used most in packaging goods.

Stainless steel

staples

- High corrosion resistance.

- Can be used in salty environmeny mainly 316.

Used for applications that require long lasting durability.

Aluminum

staples

- Middle of the way in corrosion protection

- Easier to cut through without damaging your equipment

Widely used in saw mills.

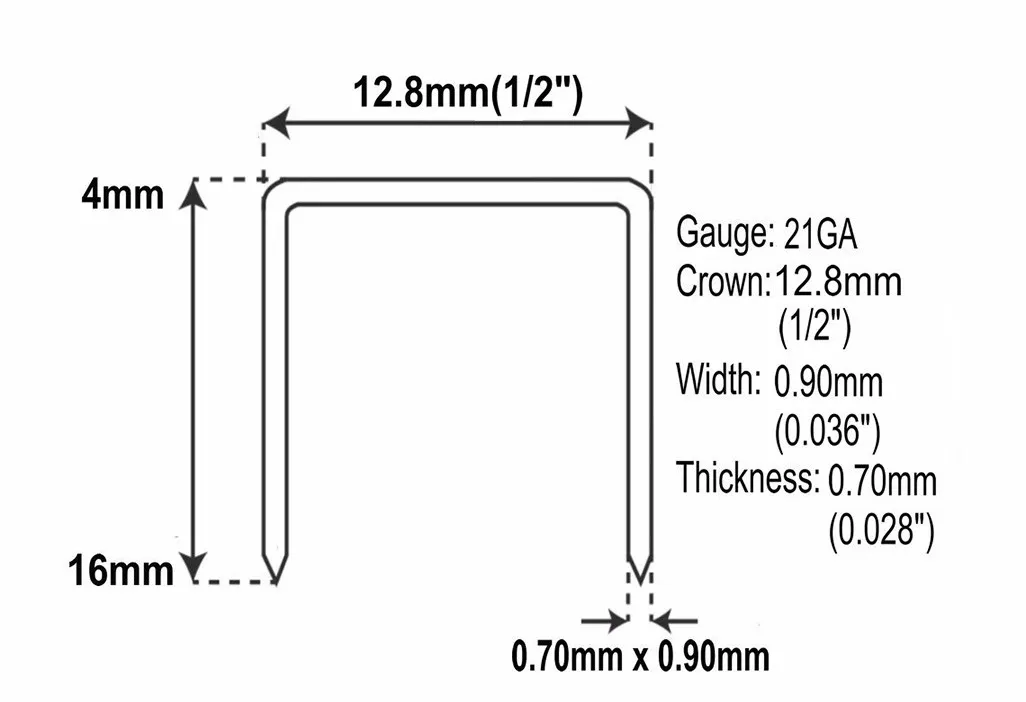

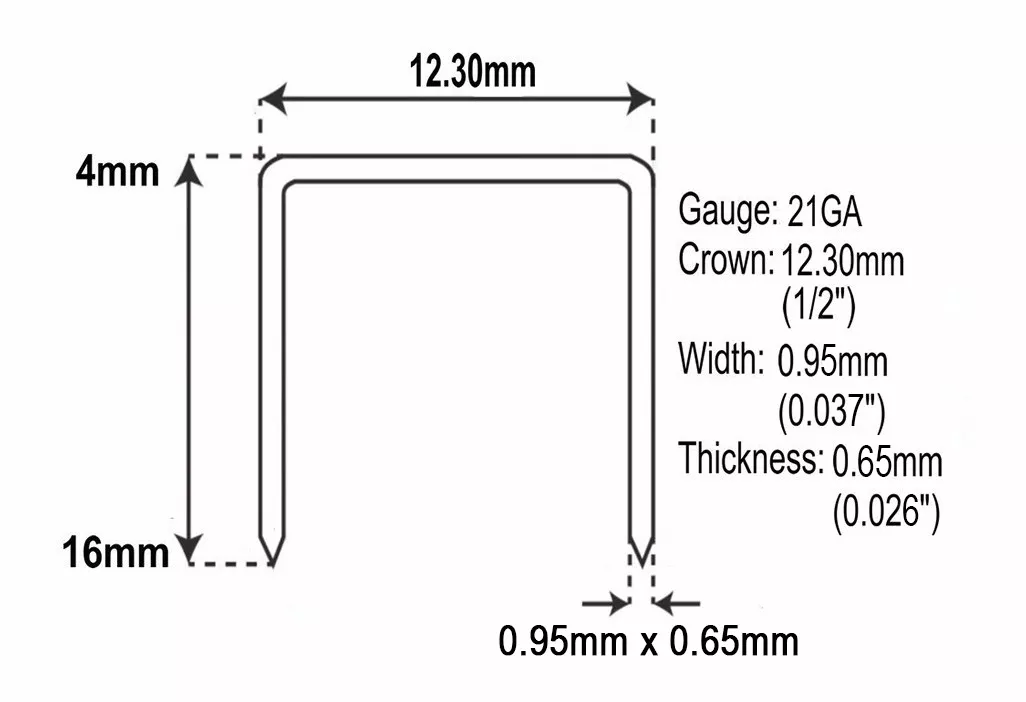

Staple Wire

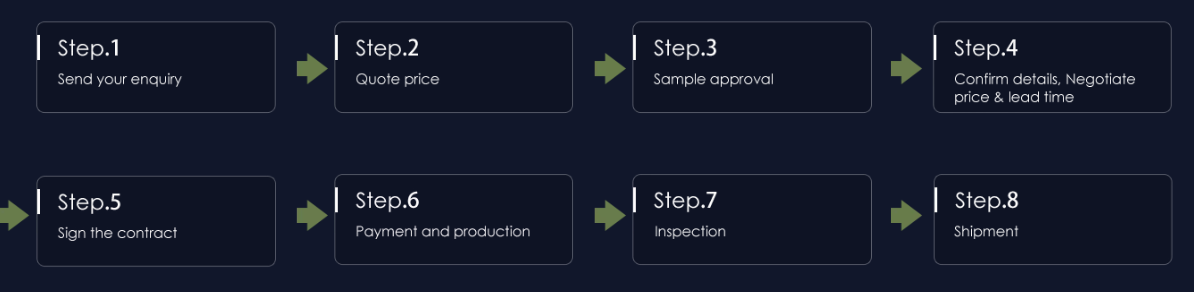

The staples wire dimensions. We divide the staple wires into the following three categories, fine wire, medium wire, and heavy wire — all with their specific uses for different applications.

Fine wire

Applications:

Furniture Upholstery, Vinyl, and trim, Picture frames, Automotive upholstery, Labeling

Medium wire

Applications:

Heavy wire

Applications:

Guage

| Gauage | 22 | 21 | 20 | 18 | 17 | 16 | 15 | 14 | 10.5 |

| Fine Wire | ✿ | ✿ | ✿ | ||||||

| Medium Wire | ✿ | ||||||||

| Heavy Wire | ✿ | ✿ | ✿ | ✿ | ✿ |

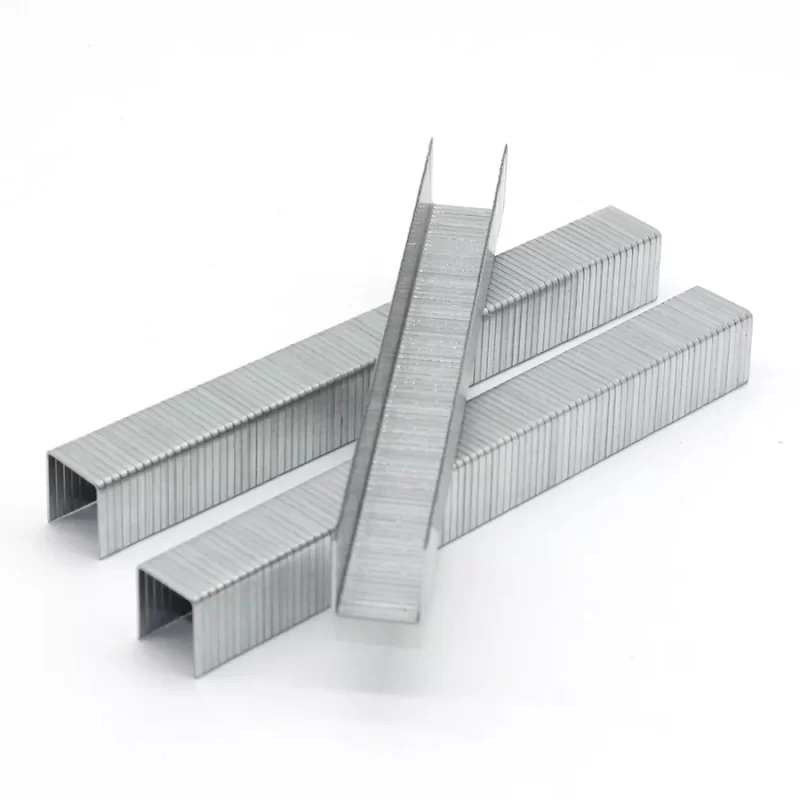

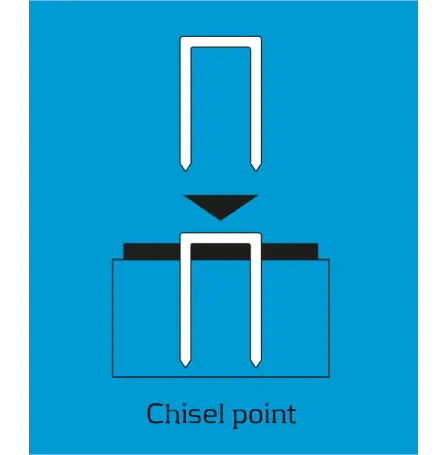

Staple Point

Chisel point staple

The staple point is the first part of the staple coming in contact with the fastening material. The staple points come in various designs, where all are specialized to provide the correct holding power for the application. We use the most common design, the chisel point design.

Chisel point staple has the design of the letter V, where the two flat inclined side meets at a sharp angle. The design makes it possible to drive the staple straight into the material to the crown of the staple.

Staple Crown

The staple crown is the top middle part of the staples holding the two legs together. There are three types of crowns (narrow crown staples, medium crown staples, wide crown staples).

Narrow crown staples

Applications:

Our narrow crown staples:

Medium crown staples

Applications:

Our medium crown staples:

Wide crown staples

Applications:

Our wide crown staples:

Fine wire staples are particularly suited

to these tasks.

Upholstery

Vinyl and Trim

Upholstering Chairs

Picture Frames

Furniture Frames

Fastening Fabrics

Type of Fine Wire Staples

Welcome To Visit Our Factory

Al-Madina Steel is one of the most important leading companies in the manufacture of fasteners in the Middle East. We are present in the Arab Republic of Egypt, where the unique location between the countries of the world from the East and the West. We have been present for more than 15 years. We are proud to export to many Arab, African, European and American countries, as the countries we export to have reached more than 45 countries around the world are proud of our quality and our goal is always and forever Quality first and foremost and the trust of our customers and maintaining them for a permanent relationship is what we aspire to and strive for.

FAQ

STAPLES

Getting the right staple length is crucial when deciding which staple you should choose. The thickness or density of the material you are fastening determines what leg length you should use for your application.

we talk about the staple wire, we mean the staples wire dimensions. For simplification, we divide the staple wires into the following three categories, fine wire, medium wire, and heavy wire — all with their specific uses for different applications.

Yes, we can provide professional outer packaging design.

Almost any fine wire and medium wire staples can be used for upholstery.

Factory

Yes,we not only have our own factory.

We are pleased to send you the sample to test the quality and market.

Yes, OEM service is available.

It usually takes about 20-30 working days to produce one order.

Normally T/T 30% in advance and T/T 70% before shipment.

Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

We always pay great attention to quality control from the very beginning and every product was tested piece by piece before delivery.

Yes, we have CE, SGS,ISO, ect.